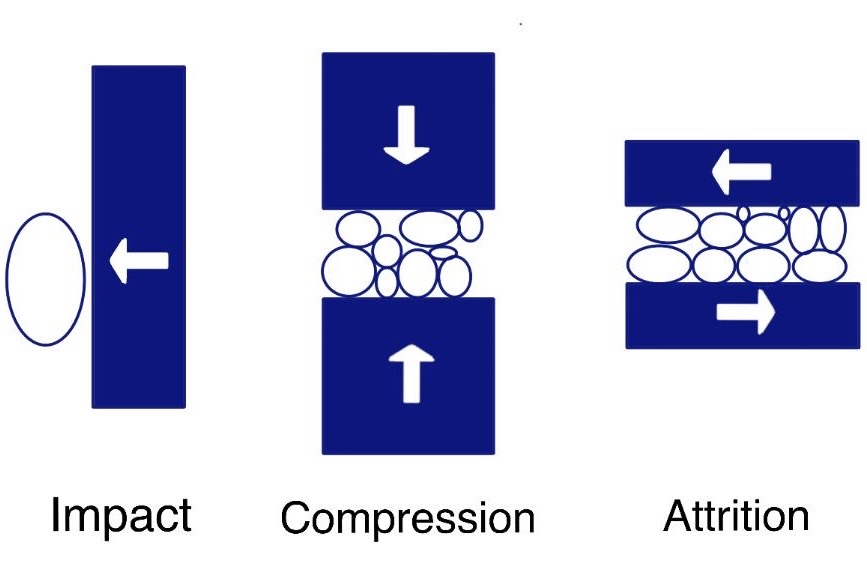

Ostwald ripening is a phenomenon that occurs in suspensions, involving changes in particle size distribution and the polymorphic form of a drug. In this process, smaller crystal particles dissolve and then redeposit onto larger crystals, leading to the growth of larger particles over time.

Mechanism and Mathematical Description of Ostwald Ripening

Particle growth is a destabilizing process resulting from temperature fluctuations during storage. Particle growth is particularly important when the solubility of the drug is strongly dependent on the temperature. Thus, when temperatureis raised, crystals of drug may dissolve and form supersaturated solutions, which favor crystal growth. This can be shown using the Kelvin equation as applied to a particle suspended in a saturated solution:

$$ \ln(\frac c{c_0})=\frac{2\gamma M}{NkT\rho R} $$

where c is the solubility of a small particle of radius R in an aqueous vehicle and co is the solubility of a very large crystalline particle; γ is the interfacial tension of the crystal, ρ is the density of the crystal, and M is the molecular weight of the solute. N is Avogadro’s number, k is the Boltzmann constant, and N × k = 8.314 × 107 ergs−1 mole−1. The ratio c/co defines the supersaturation ratio that a large crystal requires in the aqueous solution saturated with respect to the small particle.

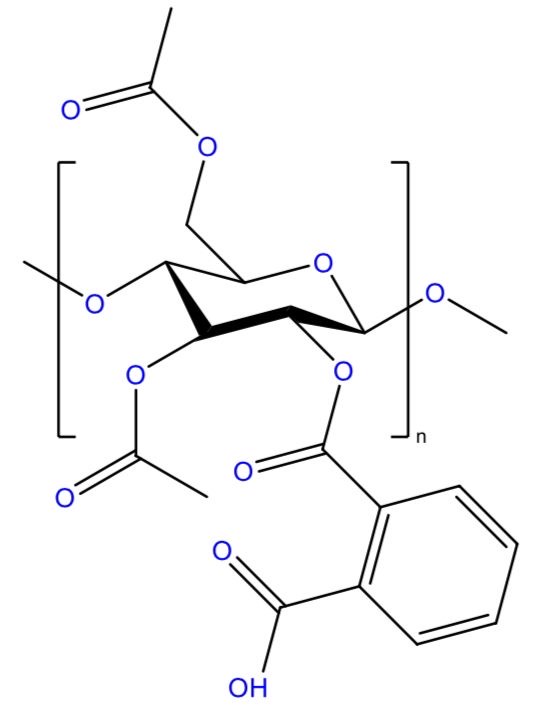

According to the equation, as the radius of curvature of a protruding crystal decreases, the protrusion will require a correspondingly larger supersaturation ratio before it can grow. The radius of curvature of a protrusion must equal that of the pore of the polymer on the crystal surface.

Controlled Ostwald Ripening

Inhibition of sulfathiazole crystal growth by polyvinylpyrrolidone. The polymer forms a noncondensed netlike film over the sulfathiazole crystal, allowing the crystal to grow out only through the openings of the net. The growth is thus controlled by the pore size of the polymer network at the crystal surface. The smaller the pore size, the higher is the supersaturation of the solution required for the crystals to grow.

A control unit was used to monitor crystal growth. The inhibition of growth by polyvinylpyrrolidone (PVP) in acetaminophen suspensions was also studied. According to these researchers, segments of the PVP polymer attach to the free spaces on the drug’s crystal lattice. The polymer is then surrounded by a hydration shell. The adsorbed segments of the polymer inhibit the crystal growth of acetaminophen by forming a barrier that impedes the approach of drug molecules from the solution to the crystal surface. High-molecular-weight PVP polymers are more effective than low-molecular-weight ones. The adsorption of the polymer on the crystal surface becomes more irreversible with longer chain lengths.

Reference:

- Sinko, P. (2011). Martin’s Physical Pharmacy and Pharmaceutical Sciences. Baltimore, : Lippincott Williams & Wilkins, a Wolters Kluwer business.