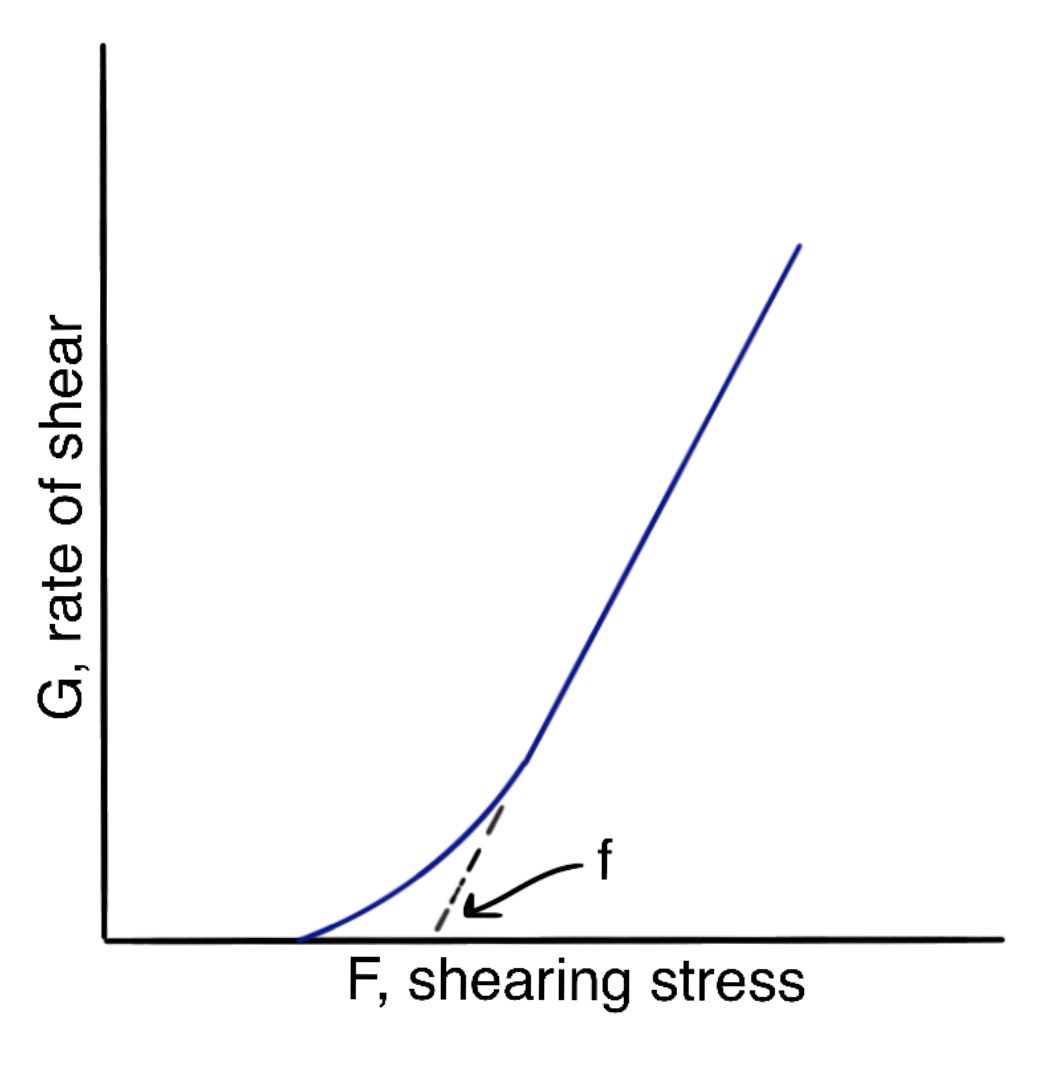

A pharmaceutical suspension is a coarse dispersion in which insoluble solid particles are dispersed in a liquid medium. The particles typically have diameters greater than 0.1 μm. Under a microscope, some of these particles can exhibit Brownian movement if the dispersion has low viscosity.[1]

Interfacial Properties of Suspension

Because suspensions are dispersions of one phase within another, the process of dispersion creates a tremendous increase in interfacial area between the dispersed particles or droplets and the dispersion medium. When considering the interfacial properties of dispersed particles, two factors must be taken into account, regardless of whether the dispersed phase is solid or liquid. The first relates to an increase in the free energy of the surface as the particle size is reduced and the specific surface increased. The second deals with the presence of an electrical charge on the surface of the dispersed particles.[2]

surface free energy

When solid and liquid materials are reduced in size, they tend to agglomerate or stick together. This clumping, which can occur either in an air or liquid medium, is an attempt by the particles to reduce the excess free energy of the system. The increase in surface free energy is related to the increase in surface area produced when the mean particle size is reduced. It may be expressed as:

$$ ΔG=γΔA $$

where ΔG is the increase in surface free energy in ergs, ΔA is the increase in surface area in cm2, and γ is the interfacial tension in dyn/cm, between the dispersed particle or droplet and the dispersion medium. The smaller ΔG is, the more thermodynamically stable is the suspension of particles. A reduction in ΔG is effected often by the addition of a wetting agent, which is adsorbed at the interface between the particle and the vehicle, thereby reducing the interfacial tension. This causes the particles to remain dispersed and settle relatively slowly.[2]

Unfortunately, in solid–liquid suspensions, the particles can form a hard cake at the bottom of the container when they eventually settle. Such a sediment, which can be extremely difficult to redisperse, can lead to dosing errors when the product is administered to the patient.[2]

Surface Potential

Both attractive and repulsive forces exist between particles in a liquid medium. The balance between these opposing forces determines whether two particles approaching each other actually make contact or are repulsed at a certain distance of separation. Although much of the theoretical work on electrical surface potentials has been carried out on lyophobic colloids, the theories developed in this area have been applied to suspensions.[2]

Criteria for a Formulated Suspension

An acceptable suspension should have several key qualities. The suspended material should not settle rapidly. Moreover, particles that do settle should be easily redispersed into a uniform mixture upon shaking. The suspension must also be of a viscosity that allows it to pour freely from a bottle or flow through a syringe needle. For external lotions, the product should be fluid enough to spread easily over the affected area without running off. It should dry quickly to form an elastic, protective film that resists rubbing off. Additionally, the lotion should have an acceptable color and odor.[1]

It is crucial to select the characteristics of the dispersed phase carefully to produce a suspension with optimal physical, chemical, and pharmacologic properties. Key factors include particle size distribution, specific surface area, inhibition of crystal growth, and polymorphic form changes. The formulator must ensure that these properties remain stable during storage to maintain the suspension’s performance. Additionally, the product should include readily obtainable ingredients that can be easily incorporated using standard methods and equipment.[1]

In pharmaceutical contexts, the physical stability of suspensions is defined as the condition where particles do not aggregate. Additionally, the particles should remain uniformly distributed throughout the dispersion. Since this ideal is rarely achieved, it is important to note that if particles do settle, they should be easily resuspended with moderate agitation.

Reference:

- Sinko, P. (2011). Martin’s Physical Pharmacy and Pharmaceutical Sciences. Baltimore, : Lippincott Williams & Wilkins, a Wolters Kluwer business.

- Felton. L. (2013). Remington Essentials of Pharmaceutics. London. UK: Pharmaceutical Press.